Project planning

The holistic project planning of our innovative and customized plastic components is the basis for applying our many years of know-how in a targeted manner.

From the first draft of the product to the development of the injection molding tools, KLT is the safe and efficient partner for your project.

Development

From target specifications and a result-oriented development consultation with the customer, our specialists can develop a completely individually tailored solution proposal – for new developments or series optimization alike.

This is supported by modern CAD / CAM systems, as well as the possibility of a simple data exchange of all formats via EDI.

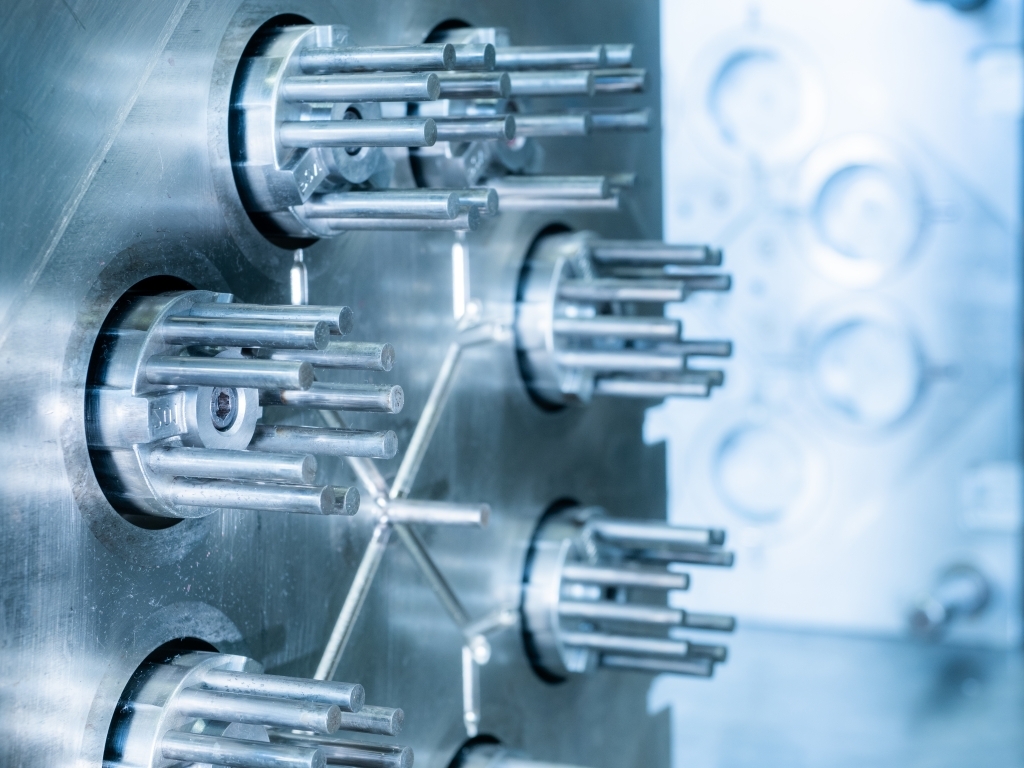

Toolmaking

The development of individual and custom-fit injection molding tools is the basic requirement for high-quality plastic components. That’s why we are particularly proud of our own tool shop, which can manufacture tools up to a size of 800x600mm according to customer requirements.

This offers the additional advantage of being able to respond to change requests at short notice and to carry out repairs without long waiting times. Perfect maintenance of all tools at all times is thus ensured.

KLT has a broad network and partnerships. This enables us to expand capacity with our regional toolmakers as well as with our cooperation partners worldwide.

Production

Our modern and efficient production is the heart of our company. Here we process all types of thermoplastics in 3-shift operation – on over 65 modern injection molding machines from the Arburg, Krauss Maffei and Engel brands.

In order to offer a work environment that is as efficient as possible, a state-of-the-art production hall was built in 2019:

- Technically most modern plastic injection molding machines and peripheral systems

- Multi-component injection molding process with insert technology

- Qualifications with test reports and analysis systems

- Process data monitoring and archiving of all spraying machine parameters

- Production from batch size 1

Quality

Our quality and environmental policy forms the basis for our daily actions. That is why we are certified according to DIN ISO 9001:2015 and VDA 6.1:2016.

With the latest 3D coordinate measuring technology and optical measuring machines, KLT is well equipped to test our products, from prototypes to large series parts.

Plastic-specific material tests are carried out in the in-house laboratory as well as at recognized institutes and universities. The use of innovative CAQ software comprehensively supports these processes.

State-of-the-art injection molding machines and production islands with integrated robot systems ensure stable processes at the highest level.

Logistics

Our many years of experience in dealing with Kanban, Just In Time and consignment warehouses give our customers around the world the confidence they need in our efficient logistics processes.